Categories: Fireproof sealing material series

| model | Minimum order quantity | Unit size | Unit weight | EXW price | Supply capacity | Packaging form |

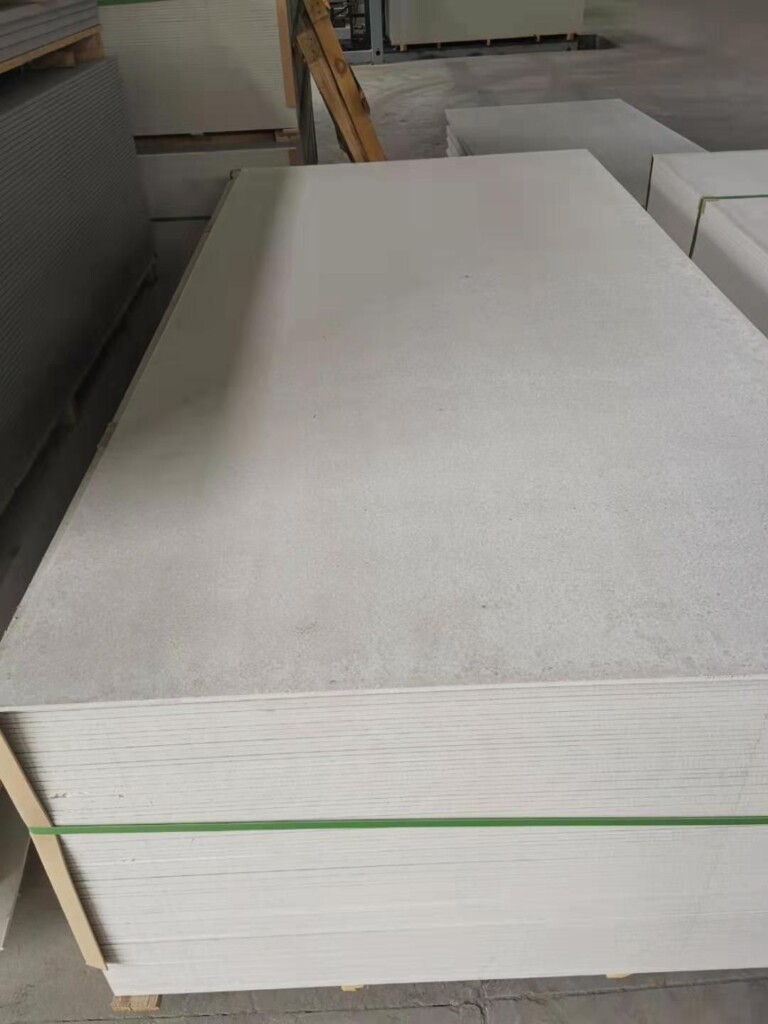

| 10mm thick | 200 sheets | 1.2m*2.4m*10mm | 45kg/sheet | 9.8 USD per sheet | 1000 sheets per day | Wood pallet |

| 8mm thick | 250 sheets | 1.2m*2.4m*8mm | 36kg/sheet | 8.4 USD per sheet | ||

| 5mm thick | 400 sheets | 1.2m*2.4m*5mm | 22kg/sheet | 5.3 USD per sheet |

Composition: It is mainly composed of siliceous materials (such as quartz powder) and calcareous materials (such as quicklime), with the addition of reinforcing fibers (such as asbestos, cellulose fibers, etc.) and a certain amount of additives, and is made through high-temperature and high-pressure steam curing processes. In asbestos free calcium silicate boards, other fibers are usually used instead of asbestos to avoid potential health hazards caused by asbestos.

Production process: Firstly, the raw materials are mixed in a certain proportion to make a slurry, and then formed through the board making process. Next, curing is carried out in a high-temperature and high-pressure saturated steam environment, causing various components in the slab to undergo chemical reactions, generating calcium silicate crystals with tobermorite as the main mineral component, ultimately forming calcium silicate boards with high strength and good performance.

Excellent fire resistance: Calcium silicate board is a non combustible material with a fire rating of up to A1. When a fire occurs, it can effectively prevent the spread of the fire and provide valuable time for personnel evacuation and firefighting rescue. For example, using calcium silicate board in key areas such as building passages and firewalls can greatly improve the fire safety of buildings.

High strength: It has high strength and hardness, and can withstand certain weight and impact forces. It can be used for building partitions, ceilings, and other parts, and can maintain structural stability even on ceilings with heavy equipment installed, such as air conditioning equipment.

Good thermal insulation performance: The internal structure of calcium silicate board gives it a certain degree of thermal insulation performance. Its low thermal conductivity can effectively reduce heat transfer, help reduce building energy consumption, and improve indoor comfort.

Good waterproof and moisture-proof performance: Although it is not a specialized waterproof material, calcium silicate board itself has a certain hydrophobicity and can maintain good performance in humid environments. Reasonable use of calcium silicate board in areas with high humidity such as bathrooms and kitchens can effectively prevent damage to the board due to moisture.

Excellent sound insulation performance: Calcium silicate board can effectively block the propagation of sound and create a quiet environment indoors. In places with high requirements for sound insulation such as conference rooms and home theaters, using calcium silicate board as a partition material can reduce the interference of external noise.

Strong corrosion resistance: It has strong resistance to general chemicals and can resist the corrosion of acidic and alkaline chemicals. Calcium silicate board can maintain its performance and appearance in industrial environments with the presence of chemicals or areas that may be contaminated by chemicals.

Good dimensional stability: In environments with large temperature and humidity changes, the dimensional changes of calcium silicate boards are small, and there will be no significant deformation, warping or other problems due to environmental factors, ensuring the flatness and stability after installation.

Building partition wall: It is one of the ideal materials for building partition walls. It can be used to separate different spaces, such as office and residential room partitions, which not only meet the requirements of sound insulation and fire prevention, but also have good stability and durability.

Ceiling engineering: widely used in the construction of building ceilings. Calcium silicate board can provide good support and decorative effect for both home decoration and commercial building ceilings, and its fire and moisture resistance can effectively protect the structure above the ceiling.

Interior decoration: As an interior wall decoration material, it can be decorated through painting, wallpaper, panel covering, and other methods to create different styles. Calcium silicate board plays an important role in the interior decoration of some public places with high fire prevention requirements, such as hotels, shopping malls, hospitals, etc.

Exterior wall insulation system: In some exterior wall insulation composite systems, calcium silicate board can serve as a protective layer for the insulation layer, preventing the insulation material from being damaged by the external environment and improving the overall fire resistance of the exterior wall.

Copyright © 2024 Hebei Baohang Fireproof Materials Co., Ltd All Rights Reserved. Privacy Policy